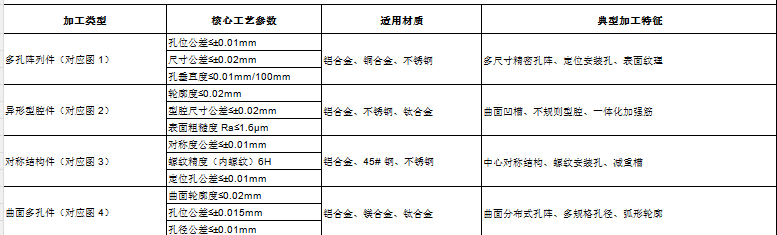

| Name: | Batch Precision Machined Parts Products |

|---|---|

CNC precision machining parts product introduction:

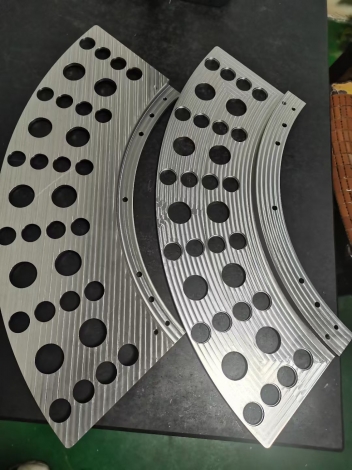

By relying on high-precision CNC machining equipment, we can achieve integrated precision machining from porous arrays, complex cavities to curved and irregular parts.

The core technological features are as follows:

1. Ultra high precision detail control like the first porous array component, capable of achieving micrometer level hole tolerance, batch processing hole consistency error<0.01mm, suitable for high-precision assembly scenarios; The third part with threads and symmetrical structure meets the design requirements for thread accuracy and positioning hole tolerance simultaneously, without the need for secondary processing.

2. The second irregular shaped cavity part of the integrated molding of complex structures, which completes the processing of complex features such as multiple curved surfaces and irregular grooves in one go to avoid splicing errors; The fourth curved porous component has a contour error of less than 0.02mm and is compatible with precise distribution of holes of different sizes, balancing modeling and functional accuracy.

3. Multi material and multi feature adaptability: Whether it is precision hole arrays made of metal materials or textured cavity structures, "multi feature synchronous molding" can be achieved through CNC technology, which not only ensures the structural strength of the parts, but also simplifies the production process and shortens the delivery cycle.