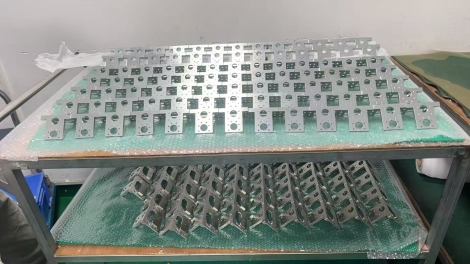

| Name: | Batch Precision Machined Parts Products |

|---|---|

Batch precision machining parts product introduction:

By relying on standardized production systems and refined process control, we achieve efficient output and quality consistency in batch part processing. All parts are polished through multiple precision processes, from raw material selection to finished product inspection, following a unified standard throughout the entire process, ensuring that the dimensional accuracy, surface smoothness, and structural stability of each product are highly consistent.

Core technological features:

1. Standardized batch production: adopting automated production lines and modular processing flow, greatly improving production efficiency, while strictly controlling batch errors to meet the needs of large-scale order delivery.

2. Precision process control: Integrating core technologies such as CNC milling and turning, coupled with high-precision detection equipment, to achieve micrometer level size control, with no burrs on the surface and uniform texture, suitable for high demand assembly scenarios.

3. Stable quality output: Establish a full process quality traceability system, with raw materials, processing parameters, and finished product testing data available throughout the entire process, ensuring quality stability and reliability throughout mass production.

Dimensional tolerance: ± 0.01~± 0.03mm; Processing cycle: ≤ 2min/piece